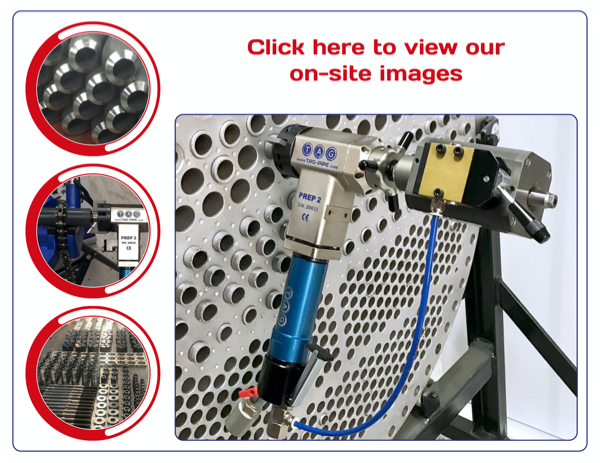

TAG PIPE BEVELLING MACHINE PREP 2

RANGE: 23 - 42mm i/d / 0.9 - 1.5" i/d

(optional from 12.5mm i/d / 0.5" i/d)

Try our small pipe beveling machines & 23-42mm interior & exterior bevelers.

- Functions: External bevelling / internal bevelling / elbow and fittings bevelling / facing, counter-boring / weld removal / J-prepping and facing of tube plate

- Materials: Any kind of steel and exotic alloy

- Power: Pneumatic, electric or battery (110v or 220v)

The smallest in our range of i/d locking, direct in-line feed end prep machines. The PREP 2 is small, light weight, yet powerful, in electric, battery (110v or 220v) or pneumatic drive form. A 4-jaw tool holder (chuck) allows use of up to 4 form tools to enable weld preparation of thin wall tube, or heavy wall pipe.

Simultaneous external and internal bevelling and facing of tubes is simple, ideal for accurate repetitive work. It's size, power, and functionality, make it extremely popular in high volume heat exchanger work, tube facing, weld removal, and J-prepping of the tube plate. Also used extensively on power station shutdowns for boiler panel bevels. Try our small pipe beveling machines & 23-42mm interior & exterior bevelers today.